DOUGCO was established in 1964 as a Mass Finishing Job Shop offering mechanical surface finishing, including vibratory and tumble deburring and burnishing. We also offer a passivation process to passivate the finished surface and resin impregnation to seal porous metal castings. Contact us to develop the process that best fits your needs. (Note: Dougco does not do chrome plating, anodizing, painting, etc.)

What is deburring?

Broadly speaking, deburring removes material from the outside of a part, leaving the finished part smooth, but with a dull and distinctive finish. For pieces shaped like a pot, the inside of that pot will not be deburred using our process.

What is burnishing?

Again, broadly speaking, burnishing will clean a part and make it shiny, while also hardening the outside of the part.

Our processes produce clean, dry parts with surface finishes suitable for direct use, or prepped for additional manufacturing steps at another facility such as plating, anodizing, painting, powder coating, etc.

We will match the surface finish on an existing part, or develop and customize a new finish to meet your requirements.

Our resin impregnation process is a vacuum/pressure impregnation process with a high temperature cure. Impregnation will not physically affect castings in any way except to seal the pores. Impregnated parts may then be plated, painted or powder coated, etc.

Members of

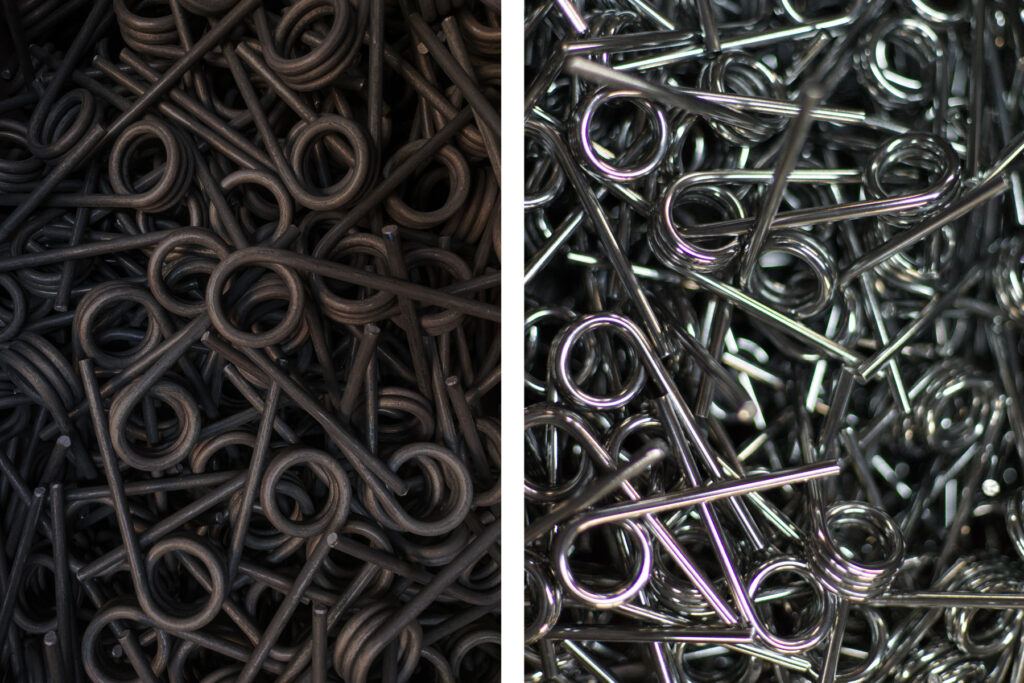

Before / After photo: Springs

Before / After photo: Art Casting